While much attention has been given to energy use in crop cultivation and irrigation, the energy demands of post-harvest activities – such as processing, cold storage and transport - are equally critical. These post-harvest stages are often where significant food loss occurs due to malfunctioning infrastructure and unreliable power. Approximately 14% of the world’s food valued at USD 400 billion is lost each year between harvest and the point of sale

The deployment of decentralized renewable energy technologies is gaining momentum across the Asia-Pacific region in the form of solar-powered milling systems, biogas digesters and cold storage

The deployment of decentralized renewable energy technologies is gaining momentum across the Asia-Pacific region in the form of solar-powered milling systems, biogas digesters and cold storage based on CO2 or ammonia technologies. Such innovations not only reduce emissions and operating costs but also enhance the resilience of rural communities to climate shocks. When integrated with energy efficiency measures, they play a crucial role in climate mitigation and advancing sustainable, inclusive agri-food systems – especially in the post-harvest phase where energy demand is significant

Technological development and trends

Post-harvest processing

Post-harvest processing refers to all the steps that transform raw agricultural produce into storable, market-ready products. These include drying, cutting, threshing, milling, winnowing and additional processes like fermentation, sterilization, meat and dairy processing, and cold storage. Each stage relies on energy to maintain quality, extend shelf life and reduce losses.

Drying, which removes moisture from crops like grains, tea etc. to prevent spoilage and reduce transport weight, is a critical first step after harvest. It plays a vital role in minimizing storage losses and reducing the risk of mold and aflatoxin contamination (a family of toxins produced by certain fungi on agricultural crops), especially for crops like nuts and grains. While natural sun drying is common in developing countries, it is labor-intensive and weather dependent, and can also result in increased losses due to pest and rodent attacks. Mechanical dryers offer a more controlled alternative but require significant energy input and are often inaccessible to smallholders due to high upfront and maintenance costs, adequate size availability and lack of knowledge regarding their use

Threshing separates grains from panicles – done manually, with animal power or via mechanical threshers. Winnowing and cleaning follow, removing broken grains, straw and sand through screening and sifting to prevent mold and insect infestation and improve taste and appearance. In many places in the Asia-Pacific region, these processes are commonly done using manual or simple and often energy-inefficient tools.

Milling involves grinding or polishing grains like rice or maize, manually or with milling machines. However, yields from milling machines are dependent on the method, crop conditions and operator skills, and low maintenance and poor calibration can reduce yields significantly. Studies show that rice milling yields in small villages across several Asian countries can drop to 57%, well below the ideal of 71% to 73%, mainly due to poor maintenance, small-scale operations and improper machine calibration

Rising energy demands in grain drying drive diverse solutions

Grain drying is essential for preserving crop quality, especially in Asia, which produces 90% of the world’s milled rice

One such technology is the solar bubble dryer (SBD), which uses solar energy in a sealed, bubble-like structure to dry grains, cutting energy use and GHG emissions by over 50% compared to traditional methods

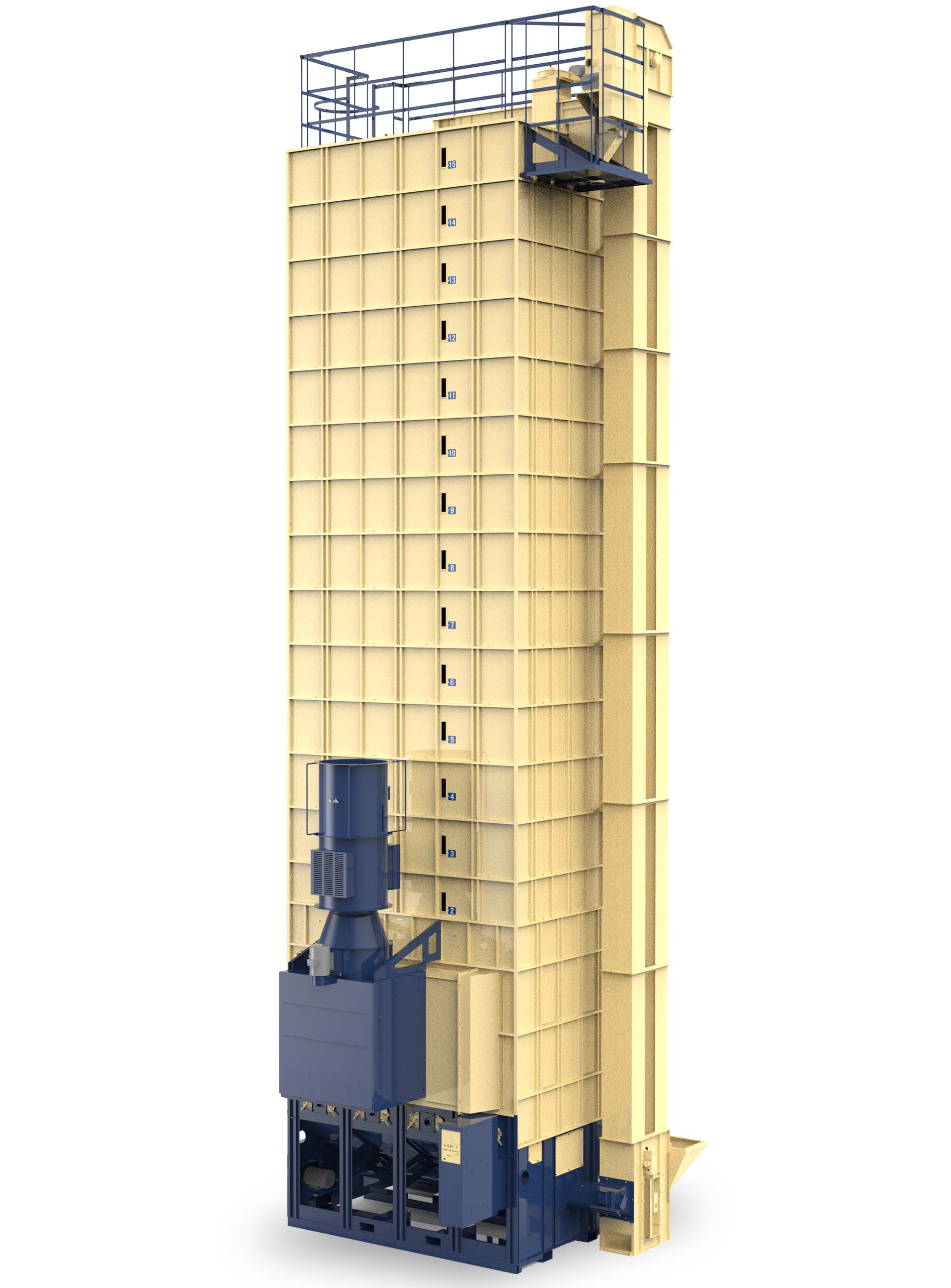

The flatbed dryer (FBD) is a common drying method in Southeast Asia. It works by blowing heated air through a perforated floor beneath a shallow bed of grain. While it is cost-effective and energy efficient, it requires a larger land area compared to other systems. In contrast, the recirculating columnar dryer (RCD) offers faster drying by continuously recirculating heated air within a vertical column, at a range of 40°C–80°C depending on moisture content

Efficient post-harvest drying is vital to prevent losses in Asia, where 90% of the world's milled rice is produced

These conventional dryers discussed above, although still in use, are gradually being replaced by more energy-efficient and smart systems. For example, smart dryers with cloud-based controls and real-time monitoring are increasing in high-income regions like Japan. These systems reduce energy consumption by up to 25% by improving drying precision

Renewable energy for agro-processing

Agro-processing systems powered by standalone renewable energy or mini-grids are emerging as cost-effective solutions that reduce emissions, support decentralized rural infrastructure and minimize labor-intensive processing. As part of this shift, solar-powered mills are increasingly preferred over diesel-powered alternatives due to ease of operation, lower maintenance costs and elimination of fuel expenses

Sustainable bioenergy is a valuable renewable resource for electricity, heat and transport fuels in the agri-food sector. Biomass by-products like bagasse from sugarcane processing are used in India, the Philippines, Thailand, and Viet Nam to power sugar mills, enabling energy self-sufficiency and even producing exportable electricity

Keeping it cool with advanced refrigeration innovations

Refrigeration has transformed food consumption and storage patterns, enabling extended preservation, diversified diets and global food trade. However, it has also contributed to climate change through energy consumption and refrigerant emissions. The refrigeration sector, including air conditioning, contributes roughly 17% of global electricity consumption, even exceeding 40% of total national electricity demand in some countries

The refrigeration sector, including air conditioning, contributes roughly 17% of global electricity consumption

In Asia, refrigeration technologies have advanced significantly, focusing on energy efficiency and sustainability. Adaptive or inverter compressors, which adjust their speed based on cooling demand, are prevalent in the region. These compressors operate at variable speeds, reducing energy consumption and enhancing operational efficiency compared to traditional compressors. Vacuum insulation panels (VIPs) are utilized to improve insulation performance in refrigeration appliances. VIPs achieve super low thermal conductivity, significantly reducing heat transfer and enhancing energy efficiency. Some refrigerators now contain convertible freezer compartments, allowing users to switch between freezer and refrigerator modes based on their needs, optimizing energy usage and storage efficiency. Modern freezers often feature microprocessor-controlled temperature settings and defrost sensors, allowing for precise temperature regulation and efficient defrost cycles, which help save energy and extend the appliance’s lifespan.

Blast freezing is a widely used but energy-intensive process where pallets of fresh produce are placed in large freezer rooms and subjected to rapidly circulated cold air to quickly preserve quality for safe storage and transport. To address the high energy demands of this method, several innovative solutions are emerging across Asia. Cryogenic freezing using liquid nitrogen offers ultra-rapid temperature reduction with significantly lower energy use, making it ideal for delicate or high-value agricultural products. However, it is more costly than conventional freezing due to the price of liquid nitrogen and operational expenses, and is therefore used selectively – notably in Japan, where the market demand for premium product supports the adoption of such advanced methods.

To enhance energy efficiency in more cost-sensitive contexts, freezer spacers are commonly used for fruits and vegetables to enhance airflow between stacked items, enabling faster and more uniform freezing while reducing energy consumption. Additionally, auto pressurization systems (APS) in spiral freezers help minimize cold air loss and reduce defrost cycles by balancing internal pressure, further improving operational efficiency.

As the Asia-Pacific region experiences rapid growth in food production, consumption and digital commerce, modernizing cold chain infrastructure has become essential

Chlorofluorocarbons (CFCs) and halons, once widely used as refrigerants and in industrial applications, were found to damage the ozone layer, leading to increased UV radiation exposure. While alternatives such as hydrochlorofluorocarbons (HCFCs), like R-22, have lower ozone-depleting potential, they still pose environmental risks. Hydrofluorocarbons (HFCs), including R-134a and R-404A, have high GWP, contributing to climate change. In response, new low-impact technologies are emerging. Air-based refrigeration systems, discussed in the horizon technology section below, use air instead of high-GWP gases to achieve temperatures as low as –100°C with over 50% improved energy efficiency

Energy efficiency is paving the way of cold chain logistics, but progress is still needed

Cold chain logistics encompass the storage and transport of temperature-sensitive goods across the supply chain to preserve the quality and safety of perishable food products. It relies on specialized refrigeration, temperature control systems, monitoring devices and cold storage facilities to maintain optimal conditions. However, in many developing countries, producers still store food in basic rooms instead of modern warehouses or cold rooms, resulting in substantial post-harvest losses. Upgrading these facilities not only reduces spoilage and emissions but also leads to meaningful energy savings, which can lower operational costs and shorten payback periods – enabling producers to offer goods at more competitive prices while contributing to climate mitigation goals.

As the Asia-Pacific region experiences rapid growth in food production, consumption and digital commerce, modernizing cold chain infrastructure has become essential. Valued at USD 168.24 billion in 2025 and projected to reach USD 253.92 billion by 2030, the cold chain logistics market is being reshaped by innovations focused on energy efficiency and sustainability

Automation is a key energy-saving strategy, with the adoption of automated storage and retrieval systems becoming more widespread

To meet these challenges, energy-saving technologies are becoming essential – not only to maintain product integrity from farm to consumer, but also to reduce operational costs and environmental impact. Key innovations include solar-powered refrigeration for last-mile delivery using solar panels mounted on three wheelers or electric vehicles to cool produce during transit; phase-change materials (PCMs) that absorb and release heat to maintain stable temperatures without continuous cooling; and thermal energy storage systems, which freeze water or specialized materials during off-peak hours and release the stored cooling during peak periods, cutting energy use and easing pressure on the power grid.

Japan is at the forefront of technological innovation in the cold chain sector, with significant progress in automation and energy efficiency. In 2023, GLP (a leading global investment company based in Singapore) announced the construction of two fully refrigerated warehouses in Japan, totaling 55,000 square meters. They feature advanced cold storage technologies like variable temperature zones (-25°C to 10°C) that switch between freezing and refrigeration, allowing it to cater to a wide range of customers including food manufacturers, wholesalers etc. The multi-tenant facility offers flexible storage options, allowing customers to rent small lots based on their needs

Automation is a key energy-saving strategy, with the adoption of automated storage and retrieval systems (ASRS) becoming more widespread in large-scale cold chain operations. These computer-controlled systems significantly reduce energy usage by optimizing warehouse operations such as enabling automatic high-density storage, minimizing lighting and ventilation needs and limiting door openings to prevent heat ingress. For instance, Tee Yih Jia in Singapore (a leading frozen food manufacturing company) has introduced advanced ASRS-equipped cold storage hubs that drastically improve energy efficiency while maintaining consistent temperature standards. More details on this can be found in the technology examples.

Supporting these infrastructure upgrades are smart technologies that enhance visibility, traceability and temperature control across the supply chain. IoT-enabled sensors and GPS trackers are now standard for real-time cold chain monitoring, while blockchain offers the potential to provide a secure and decentralized transaction record to support the tracing of product origins and storage conditions. Predictive maintenance and demand forecasting, powered by AI and data analytics, further optimize both energy use and logistics. On the transport side, IoT-integrated refrigerated electric vehicles and route optimization software are helping maintain cold chain integrity while reducing fuel consumption and emissions.

Cutting energy costs in dairy farming with innovative processing solutions

Dairy farms consume more energy than most other types of agricultural operations

One effective energy-saving strategy is heat recovery. Plate heat exchangers (PHEs), for example, use thin stainless-steel plates to transfer heat from warm milk to cold water flowing on opposite sides. This pre-cools milk before it enters the bulk tank, reducing the refrigeration load. PHE systems are modular and adjustable in capacity, and when supplied with very cold water, they can lower milk temperatures from around 35°C to below 18°C, cutting refrigeration energy use by up to 60%

Milk chilling and pasteurization are key areas of innovation in dairy processing

New technologies are also emerging to replace conventional chilling methods, particularly in rural and off-grid areas. Thermal battery-based chillers use PCMs to store energy as ice when electricity is available, then release it to cool milk during power outages. Similarly, solar-powered bulk milk coolers are being deployed in India and Nepal, offering reliable milk preservation with minimal carbon footprint.

In processing plants, energy-efficient pasteurization systems with heat regeneration capabilities are being adopted to reduce fuel use. These systems reclaim heat from pasteurized milk to pre-warm incoming raw milk, thereby minimizing the total energy required. Equipment like homogenizers and separators equipped with variable frequency drives (VFDs) also reduce energy usage by allowing precise motor control during standardization and cream separation.

Further efficiency gains are being realized through membrane filtration technologies such as ultrafiltration and reverse osmosis. These methods allow for concentration of milk and whey with lower energy input than traditional thermal evaporation, while also improving yield and preserving nutrients. In powder production, modern spray dryers (evaporate the liquid in milk using a stream of hot air) with energy recovery and optimized airflow systems minimize thermal losses and increase drying efficiency. Additionally, robotic milking systems are being adopted to improve overall operational efficiency.

Brewing energy efficiency and technology in tea production across Asia

Tea is one of the most widely consumed beverages globally, with several Asian countries dominating its production. China leads the world in tea output, reaching nearly 2.4 million metric tons in 2024 while India and Sri Lanka closely follow. India, contributing over 23% of global production, holds the position of the second-largest tea producer

The process of manufacturing tea comprises several stages – plucking, withering, rolling, maceration, fermentation, drying, grading and packing – all of which demand significant thermal and electrical energy. Specific energy consumption ranges between 4 and 10.4 kWh per kilogram of made tea

Among all the processing steps, withering and drying consume the most energy. Together, these stages account for over 80% of the thermal energy used, primarily for moisture removal. Meanwhile, electrical energy supports various functions throughout the production cycle, such as operating motors, fans, humidifiers and lighting. Notably, the withering phase alone consumes approximately 40% to 45% of the factory’s electricity usage

Withering marks the beginning of the tea manufacturing process. It involves reducing the moisture content of freshly plucked leaves to about 70% making them pliable and ready for rolling and fermentation

The withering phase in the tea manufacturing process consumes approximately 40% to 45% of the factory’s electricity usage

Recent innovations include improved withering troughs equipped with automated air control systems, which adjust airflow and temperature for optimized drying and reduced energy use. Additionally, more sustainable heating sources, such as biomass-fired furnaces and gasifiers, are being introduced. These systems use agricultural residues, like tea prunings and wood chips, to generate cleaner heat compared to traditional firewood. Solar drying technologies, including hybrid solar-biomass systems, also help reduce energy consumption by harnessing solar power to assist in the drying process, particularly on cloudy days. Energy can also be saved with regular maintenance, like cleaning burner dust and replacing worn parts, improving combustion and efficiency.

The final drying stage in tea processing is highly energy-intensive, often involving rotary dryers that remove moisture with hot air. For certain varieties like gunpowder tea, ball tea machines are also used to roll leaves into small pellets. Upgrading these machines to higher capacities can reduce electricity use by minimizing the number of machines needed. Additionally, heat recovery systems in dryers can further cut energy consumption by capturing and reusing waste heat. Variable speed blowers, used in both withering and drying, adjust airflow based on real-time needs, reducing thermal losses and preserving tea quality.

Innovation examples

Zero energy “Subjee-Cooler” for vegetable and fruit storage in India

RuKart’s Subjee-Cooler is a passive cooling solution that works without electricity or solar power. It uses evaporative cooling to lower temperature and maintain high humidity, where warm air is drawn through water-soaked pads. As the water evaporates, it absorbs heat and releases cooler, humid air into the storage space, keeping vegetables fresh for 5–7 days. The Subjee-Cooler is made up of seven layers of insulation walls, which lower the inside temperature by 5–21°C compared to the ambient temperature. It also maintains a high relative humidity of 85% to 90%, preventing moisture loss from stored produce. Each unit stores up to 100 kg of produce and uses just 15 liters of water daily. In trials at Sahaja Organics, five units reduced spoilage by over 50%, especially during hot months

Bioenergy for tea drying in Viet Nam

In Thai Nguyen, Viet Nam’s key tea-producing region with over 23,000 hectares of cultivation and around 91,000 small-scale processors, traditional tea drying methods using wood and charcoal release significant smoke, toxins and CO2, posing health and environmental risks. To address this, the SWITCH-Asia BEST project, led by international NGO Oxfam and the local NGO Center for Creativity and Sustainability (CCS), introduced continuous volumetric biomass gasification (CVBG) technology, which converts agricultural and forestry waste into clean-burning syngas. This innovation significantly reduces smoke, toxins, and CO2 emissions, improves processed tea quality, reduces production costs, and produces biochar as a by-product for horticulture. The project targets 2,500 agro-processing MSEs in four provinces, aiming to benefit 1.2 million people and reduce 2 million tons of CO2 by gasifying 1.4 million tons of biomass

Technology solutions

Proven technologies

Solar appliance: portable solar cold storage box

Cold Storage Japan Inc.

This portable cold storage unit operates on standard utility power (100V–260V) and can function off-grid using integrated solar panels and batteries. It supports a wide temperature range (-25°C to 10°C) for both refrigeration and freezing needs. Compatible with various voltages and requiring no additional power infrastructure, it is well-suited for diverse locations – including rural and remote areas. The system also enables auxiliary power use, such as charging devices, making it a practical solution for extending cold chain access, reducing food loss and preserving local ingredients. By incorporating a remote monitoring module, users can track product temperature, humidity and location through their computer or smartphone.

Contracting type: For sale

Technology maturity: Proven

Technology level: Medium

Place of origin: Japan

Availability: Japan

Contact: WIPO GREEN Database

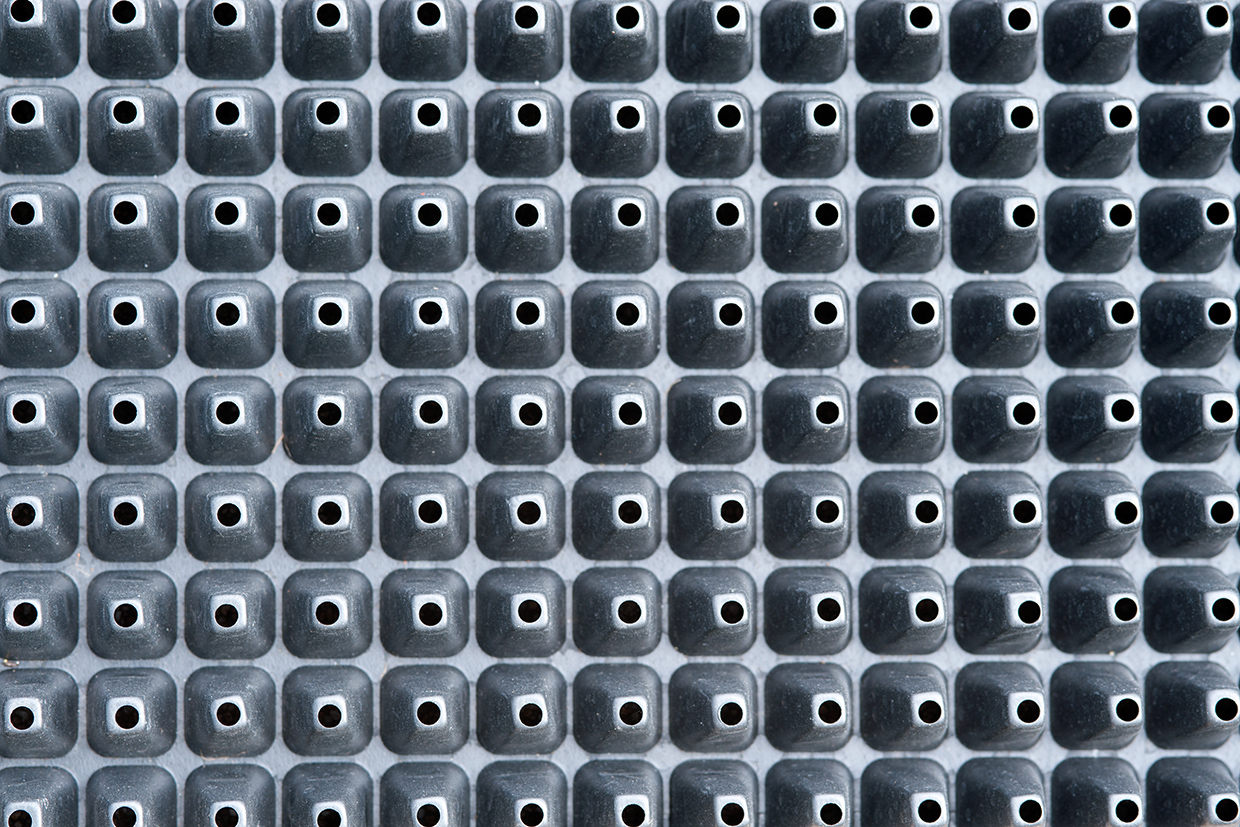

Energy efficiency: freezer spacers boosting efficiency of blast freezers

Huaian East

Freezer spacers, such as egg-crate-style plastic designs, are used in cold chain and food processing operations to improve airflow during blast freezing, cooling or tempering. Placed between layers on a pallet, these spacers enhance air circulation, speeding up freezing times and ensuring uniform temperature distribution. Their multi-directional airflow design reduces cold spots and supports product quality and freshness. Common in meat processing, cold storage and distribution centers, these reusable spacers perform efficiently in temperatures from -20°C to +45°C, with customization options down to -45°C for more extreme conditions.

Contracting type: For sale

Technology maturity: Proven

Technology level: Low

Place of origin: China

Availability: Worldwide

Contact: WIPO GREEN Database

Drying: intelligent tea withering, monitoring and control system (TWMAC)

Stesalit Automation

TWMAC is an automated solution that improves the consistency and quality of tea withering while reducing energy use. The system monitors tea leaf weight every 30 minutes by switching off the fan for about 4 minutes, tracking moisture loss against a pre-set profile. Based on the weight loss trend, it automatically controls fan operation – activating it when drying is insufficient and keeping it off when over-drying is detected. Visual alerts signal when manual hot air input may be needed. By minimizing unnecessary fan use, the system reduces electricity consumption and may shorten the payback period to under 10 months based on energy savings alone.

Contracting type: For sale

Technology maturity: Proven

Technology level: High

Place of origin: India

Availability: India

Contact: WIPO GREEN Database

Drying: solar bubble dryer

GrainPro

The GrainPro® Bubble Dryer™ is a tunnel-type agricultural dryer that uses solar or electric power to reduce moisture content while shielding crops from unpredictable weather. It features a UV-resistant transparent cover and a black PVC floor, forming a sealed chamber where solar heat or electric energy evaporates moisture. The transparent top allows solar radiation to penetrate the chamber. As the temperature rises, the moisture within the produce evaporates. Built-in ventilators then help circulate the warm air, pushing the moisture-laden air out through a designated exhaust port. This controlled airflow ensures consistent drying. Designed for efficiency, it achieves an average drying rate of 0.5% moisture content per hour and can reduce moisture from 22% to 14% in 6–8 hours under optimal conditions.

Contracting type: For sale

Technology maturity: Proven

Technology level: Medium

Place of origin: United States of America

Availability: Worldwide

Contact: WIPO GREEN Database

Drying: portable biomass-based batch grain dryer

Matharu

The MATHARU Bio-M6 is a portable batch grain dryer designed for flexibility in drying both small and large quantities of grains. It features an integrated biomass furnace that generates clean, ash-free hot air using fuels such as paddy husk, corn cobs, sawdust or wood chips. The system includes fully automatic temperature control and is designed for ease of use, reliability and quick installation in various settings. Suitable for crops such as maize, paddy, wheat, soybean, barley and rice, the Bio-M6 offers a lower operating cost compared to diesel or gas-powered dryers, supporting energy-efficient and cost-effective grain drying.

Contracting type: For sale

Technology maturity: Proven

Technology level: Medium

Place of origin: India

Availability: India

Contact: WIPO GREEN Database

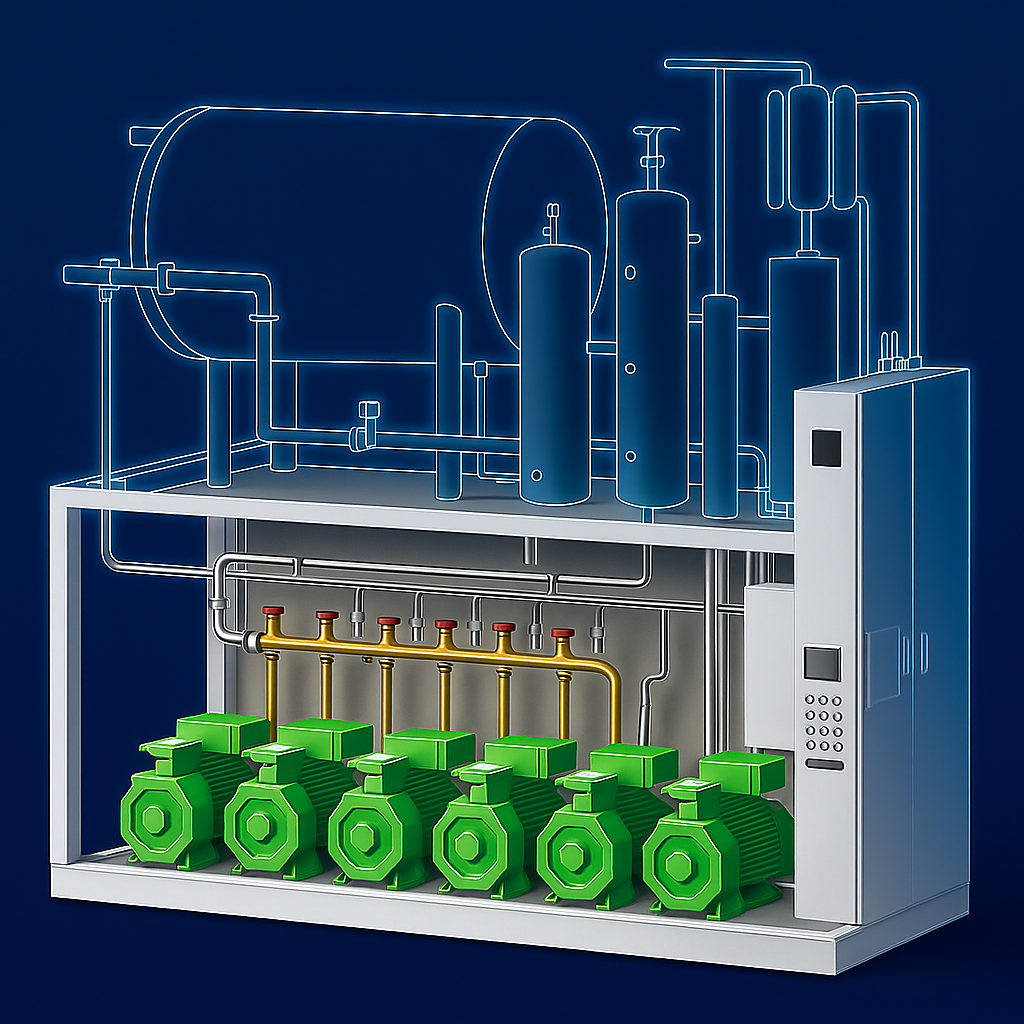

Waste-to-energy: modular biogas station

Enwise

This on-site biogas power station integrates biological digestion with advanced hardware and software to convert up to 80 tons of organic waste per day into renewable energy and high-quality fertilizer. Capable of producing up to 10,000 m³ of biogas daily, it requires 70% less space and delivers up to 100% more energy output compared to conventional systems. Designed for energy efficiency, it operates without added water, uses 50% less heat and 60% less electricity, and fits seamlessly into existing workflows – reducing labor and transport needs. Real-time remote monitoring and adaptive controls optimize performance continuously without requiring an on-site team.

Contracting type: For sale

Technology maturity: Proven

Technology level: High

Place of origin: China

Availability: China

Contact: WIPO GREEN Database

Drying: rotary dryer for tea processing

Quanzhou Deli Agroforestrial Machinery

This rotary dryer features two tray racks with 36 trays total, providing a 34 m² drying area and powered by a 36-kW electric heating system capable of reaching up to 180°C. Its rotary design ensures even heating and faster drying, while the patented air duct system allows the bottom of each sieve tray to enter the air, which quickly removes the moisture in the tea and improves the drying efficiency. Modular construction supports efficient production and maintenance. The double-door structure uses a container-style buckle for improved sealing and ease of use. Designed primarily for tea processing, it is also suitable for drying a variety of products including seafood, meat, fruits, vegetables, herbs and grains.

Contracting type: For sale

Technology maturity: Proven

Technology level: High

Place of origin: China

Availability: Worldwide

Contact: WIPO GREEN Database

Drying: recirculating batch grain dryer

Agrosaw

This indirect-heating recirculating grain dryer is designed for efficient drying of various grains, cereals, pulses, oilseeds and fodder or grass seeds. Equipped with a dynamically balanced centrifugal or axial fan, it generates controlled hot air while venting exhaust gases separately through a chimney, preventing contamination of the drying chamber. The unit uses an elevator for both loading and recirculating materials to ensure uniform drying. Thermostatic controls manage the hot air temperature based on the specific crop, and an automatic light oil burner system supports consistent performance. The insulated structure minimizes heat loss, resulting in reduced fuel consumption and improved energy efficiency.

Contracting type: For sale

Technology maturity: Proven

Technology level: High

Place of origin: India

Availability: Kenya, Saudi Arabia, South Asia

Contact: WIPO GREEN Database

Frontier technologies

Dairy processing: milk-chilling system with heat recovery

Coolsense

The VariCOOL is a milk-chilling system capable of reducing shed power consumption by up to 30%. It uses a plate heat exchanger for snap chilling, cooling milk to 6°C at vat entry while generating free hot water for shed use. The milk is then further cooled through the base pad of the milk vat. The VariCOOL can chill multiple vats simultaneously and employs variable-speed compressors and fans for energy efficiency. Unlike conventional gas-based cooling, it relies on liquid glycol as the chilling medium, minimizing refrigerant gas requirements. According to the manufacturer, this reduces emissions by up to 90% compared to older HFC-based units.

Contracting type: For sale

Technology maturity: Frontier

Technology level: High

Place of origin: New Zealand

Availability: New Zealand

Contact: WIPO GREEN Database

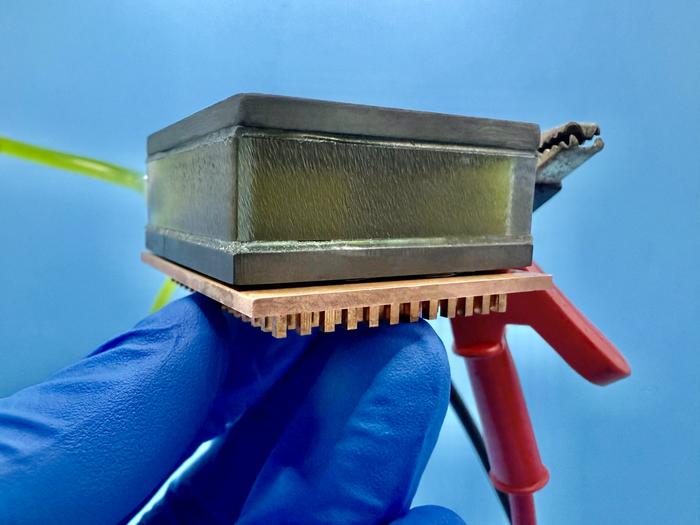

Cold storage: CO2 based cold chain refrigeration

Cold Chain Refrigeration Pte Ltd

Cold Chain Refrigeration offers energy-efficient cold room solutions using CO2 (R-744) refrigeration technology, especially for food processing, storage and retail. With an ultra-low GWP of 1, CO2 (R-744) is more environmentally friendly than conventional refrigerants such as HFCs and HCFCs. The system operates at higher pressures and offers superior heat transfer, leading to improved energy efficiency and reduced electricity consumption. A key advantage is their ability to recover and repurpose waste heat for water or space heating, further lowering overall energy demand. CO2 is also non-toxic and non-flammable, making it a safe option for indoor use. In custom cold room installations, CO2 systems provide precise temperature control, reliability and lower energy bills.

Contracting type: For sale

Technology maturity: Frontier

Technology level: High

Place of origin: Singapore

Availability: Singapore

Contact: WIPO GREEN Database

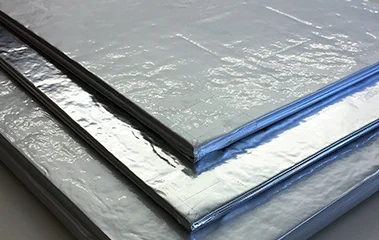

Cold storage: vacuum insulation panels

Panasonic Holdings Corporation

U-Vacua® vacuum insulation panels (VIPs) are designed to provide high thermal insulation with a low thermal conductivity of 0.002 W/mK. Using a vacuum core to limit heat transfer by conduction and convection, they offer compact insulation suitable for applications where space and energy efficiency are important. With a low GWP, U-Vacua® VIPs are used in sectors such as commercial refrigeration, cold chain storage and portable containers, and can support efforts to meet energy performance standards.

Contracting type: For sale

Technology maturity: Frontier

Technology level: Medium

Place of origin: Japan

Availability: Worldwide

Contact: WIPO GREEN Database

Cold storage: cryogenic tunnel freezer

Air products

The Freshline MP tunnel freezer is a modular cryogenic freezing system designed for rapid, energy-efficient food freezing using liquid nitrogen. Its design minimizes gas consumption, offers fast start-up and supports continuous operation for up to 20 hours per day. With freezing capacities ranging from 300 to 3,000 kg/hour, it suits various production scales. The system includes IoT capabilities for remote data monitoring and offers flexibility for standard freezing, crust freezing, individual quick freezing (IQF) and chilling. Its hygienic construction ensures quick cleaning and compliance with food safety standards, while rental options and low initial investment make it accessible for small and large producers alike.

Contracting type: For sale

Technology maturity: Frontier

Technology level: High

Place of origin: United States of America

Availability: Worldwide

Contact: WIPO GREEN Database

Cold storage: fully automated cold storage with ASRS technology

SSI SCHAEFER

SSI SCHAEFER provides warehouse automation technologies including rack-clad high-bay warehouses and automated storage and retrieval systems (ASRS) using SSI EXYZ cranes. Scalable and suitable for deep-freeze environments down to -30°C, the storage solutions support high-density configurations with direct access to each pallet position. The technologies are configured based on the specific operational needs of each facility and enable energy-efficient operations through optimal space utilization, reduced human activity in cold zones and minimized thermal losses through reduced door openings. Automated guided vehicles (AGVs) further enhance energy and workflow efficiency by streamlining internal logistics across storage, picking and dispatch areas, while also reducing manual handling.

Contracting type: For sale/service

Technology maturity: Frontier

Technology level: High

Place of origin: Germany

Availability: Worldwide

Contact: WIPO GREEN Database

Milling: solar-powered flour mill

Shakti Pumps

The solar-powered milling system is designed for off-grid and rural areas, operating independently of conventional electricity infrastructure. Powered entirely by solar panels, it reduces energy costs and supports sustainable agricultural practices. By enabling local grain processing, it minimizes travel, lowers emissions and offers a practical solution for areas with limited power access. The technology is patented and contributes to income generation and rural development goals.

Contracting type: For sale

Technology maturity: Frontier

Technology level: Medium

Place of origin: India

Availability: Worldwide

Contact: WIPO GREEN Database

Drying: smart grain dryers

Yamamoto

This grain dryer is designed to dry up to 30 tons of rice with higher milling recovery and lower energy consumption compared to conventional dryers. It features an automated control panel that adjusts hot air temperature and airflow based on load size, ambient conditions and moisture content. Compatible with biomass, diesel, LPG or steam as heat sources, the system maintains precise drying temperatures with a heat controller and suction blower that stabilizes hot air supply. Its multilayered drying chamber ensures even and efficient drying, while stainless steel screens provide durability. An integrated moisture sensor monitors grain moisture every 30 minutes and automatically stops the process upon reaching target levels.

Contracting type: For sale

Technology maturity: Frontier

Technology level: High

Place of origin: Japan

Availability: Africa, Asia, the Americas

Contact: WIPO GREEN Database

Dairy processing: spray dryer for milk powder processing

Tetra Pak

The Tetra Pak® Spray Dryer Wide Body is a flexible drying system designed for producing various powders, including milk, whey and plant-based products. It features a single or multi-venturi air distributor that ensures uniform airflow with low pressure drop, reducing electricity use. Its modular design supports scalable capacity while maintaining consistent atomization. The chamber roof cooling system minimizes powder build-up and overheating. It supports both single- and multi-stage drying, including after-drying and cooling for delicate powders. Integrated nozzle assemblies and optional fines return improve efficiency and product quality, while the shaking motion enhances air-solid contact and thermal performance.

Contracting type: For sale

Technology maturity: Frontier

Technology level: High

Place of origin: Sweden

Availability: Worldwide

Contact: WIPO GREEN Database

Dairy processing: rapid milk chiller

Promethean Power Systems

Promethean’s Rapid Milk Chiller is a modular, energy-efficient system that chills 1,000 liters of milk per day from 35°C to 4°C without relying on diesel generators. The system operates on just four hours of intermittent grid power between milking shifts, making it ideal for rural areas with unreliable electricity. The system includes a thermal storage unit, chiller and milk heat exchanger. Thermal storage is charged when grid power is available and then used to chill milk even when there is no power. This reduces fuel costs and ensures better milk quality.

Contracting type: For sale

Technology maturity: Frontier

Technology level: Medium

Place of origin: India

Availability: Bangladesh, India, Sri Lanka

Contact: WIPO GREEN Database

Horizon technologies

Cold storage: eco-friendly air-based refrigeration

The Korea Institute of Energy Research (KIER)

.png.jpg)

The Korea Institute of Energy Research (KIER) has developed an air-based refrigeration system that offers a sustainable alternative to high-GWP refrigerants like Freon and HFCs. The system uses the reverse-Brayton cycle, a refrigeration process where compressed air is cooled, then expanded to absorb heat and provide cooling without using liquid refrigerants. Its integrated ultra-high-speed compander (combining a compressor and expander on a single shaft) achieves efficient, stable operation at ultra-low temperatures. Capable of reaching -100°C, the system has experimentally been able to show over 50% higher energy efficiency than conventional vapor compression technologies, with successful cooling below -60°C in under an hour.

Contracting type: N/A

Technology maturity: Horizon

Technology level: High

Place of origin: Republic of Korea

Availability: Republic of Korea

Contact: WIPO GREEN Database

Cold storage: energy-saving thermogalvanic technology for cooling

Huazhong University of Science and Technology

Researchers at Huazhong University of Science and Technology are exploring thermogalvanic technology as a low-energy, eco-friendly alternative to traditional vapor compression in refrigerators. Thermogalvanic cells use reversible chemical reactions to produce or absorb heat, and recent advancements have improved their cooling power by 70% through chemical optimization. With refrigerators and freezers accounting for nearly 4% of global electricity use in 2019, this technology holds the potential to significantly reduce energy consumption and carbon emissions. Researchers are now developing prototypes and seeking industry partnerships for commercialization.

Contracting type: N/A

Technology maturity: Horizon

Technology level: High

Place of origin: China

Availability: N/A

Contact: WIPO GREEN Database

Cold storage: smart solar-powered freezer truck

The Hong Kong Polytechnic University.

The smart solar-powered freezer truck features extensible solar photovoltaic (PV) panels mounted on the roof to enhance energy efficiency by increasing power output. It is equipped with an energy storage system that captures and stores solar energy for use by the truck’s freezer system, while an onboard lithium-ion battery provides additional power and can be recharged using standard electric vehicle charging stations. The truck’s refrigeration system, capable of maintaining temperatures as low as -45°C, can operate for up to four hours with a fully charged battery. Additionally, the vehicle supports energy sharing with other trucks and features a smart energy management system that optimizes energy use and freezer performance. This system is designed for flexible energy input and offers extended operation with options for battery expansion, making it a sustainable solution for last-mile delivery of perishable goods. The freezer truck is now ready for commercialization.

Contracting type: N/A

Technology maturity: Horizon

Technology level: High

Place of origin: Hong Kong, China

Availability: Hong Kong, China

Contact: WIPO GREEN Database